This document was originally posted in two places:

- https://forum.revspace.nl/t/warning-why2025-badge-is-a-fire-hazard/684

- https://wiki.why2025.org/Badge/Fire_hazard

WHY2025 badge fire hazard advisory

The WHY2025 badge is a fire hazard when used with unprotected cells. Unprotected cells themselves are intrinsically unsafe and require additional safety measures which are not provided by the badge. In fact, the badge makes it worse.

Background information

Visitors of WHY2025 can get a badge, a fun electronic gadget that is a true work of art. These badges have become a tradition at this kind of conference/festival.

Designing a badge is a large effort, and in this edition it was done in just a few months. Unfortunately, with this edition’s design and intended use, the only thing preventing a fire is, basically, a thin layer of paint (actually resin (solder mask)).

The WHY2025 badge was designed to be powered by 2 Li-Ion 18650 battery cells connected in parallel. The cells provided to visitors are of the “unprotected” kind and thus capable of providing a very large short circuit current. A short circuit can cause parts to overheat, posing a burn or fire risk to nearby materials (e.g. skin, clothing, luggage). Due to the design of the badge, there are several ways a short circuit could occur.

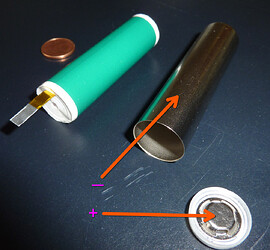

Image from Tweakers

TL;DR

Never have the 18650 cells installed in the WHY2025 badge; return the 18650 cells to the Badge tent or keep the 18650 cells themselves in a sturdy non-conductive enclosure if you want to keep them for different purposes (e.g. in a safe powerbank).

It may be safe to use the badge with an external USB power supply instead, as those will typically provide the necessary protections.

Nomenclature: “batteries” vs “cells”

In the remainder of this document, a distinction is made between these terms, following the definitions in EN 61960, a European standard titled “Secondary cells and batteries containing alkaline or other non-acid electrolytes - Secondary lithium cells and batteries for portable applications” (based on IEC 61960).

A cell is a building block for creating a battery.

A cell derives electrical energy derived from a chemical reaction. Notably, according to EN 61960, “It is not ready for use in an application because it is not yet fitted with its final housing, terminal arrangement and electronic control device”.

A battery consists of one or more cells, an “adequate housing”, and if necessary, control electronics. Common examples of batteries include powerbanks and powertool batteries. Batteries are also found in laptops and phones, and those are usually integrated in the same housing.

The 18650 Li-Ion cells

Li-Ion battery technology comes with inherent risks. These risks can be mitigated to the point that they can be used safely in consumer products, but the WHY2025 badge does not come with sufficient protection.

The cells themselves are dangerous when not handled carefully. Almost the entire metal surface of the cell is the negative or “-” side, with a small portion on top that is the positive or “+” side. The outer ring on the “+” end of the cell is connected to the “-” too, and there is an insulating ring between those.

When the “+” of the cell is connected with the “-” side with a negligible resistance (i.e. short circuit), it is said that it could explode if that condition lasts long enough. We have not tested this with the WHY2025 badge cells, but there are videos of similar cells doing exactly that, and some that didn’t. The ones that don’t explode still do get very hot.

Image from Wikipedia

A thin layer of a sturdy plastic foil keeps most of the negative contact surface covered. This provides electrical insulation but it can be damaged by sharp objects, or sometimes even during insertion into cell holders. If the “+” and “-” side are then connected by means of a conductive material, a short circuit occurs which leads to very high temperatures, capable of igniting common materials.

There exist protected cells that have a protective circuit at the end of the cell, wrapped together with the cell in one protective foil. These are popular for use with flashlights. When used in an enclosure, those are very safe against short circuits: the protective circuit protects against external short circuits, while the enclosure and sufficient insulation/clearance within the sleeve protect against internal short circuits in the “battery” (protected cell).

With a protected cell without housing, something could still cut through the foil and separate the protective circuit, but this does not happen easily. With careful use, they can be somewhat safe to use without an enclosure. A similar design (but with flat “pouch” style cells instead of cylindrical) was used in the SHA2017 and MCH2022 badges.

The WHY2025 badge cells do not have a built-in protection circuit. Commonly available protected 18650 cells don’t fit in the badge’s cell holders because they are slightly longer.

The badge, being a badge, does not have an enclosure and as such doesn’t provide the “adequate housing” that is necessary for a battery. The cells are handed out without a carrying case, so unless you know what you’re doing, you can’t even transport them safely.

The badge itself: short circuit risk

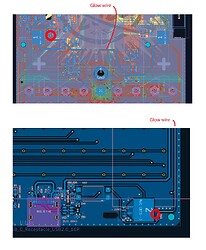

The problems exist in the “Carrier” PCB of the badge. This is the large circuit board to which the two cell holders are soldered. There are several design issues that increase the risk of a short circuit.

The design of the power source of the badge resembles that of a powerbank. In fact, it actually uses a powerbank IC (chip) at the heart. Instead of providing power to external devices, it provides power to the rest of the badge, but apart from that, it is a basically just a powerbank.

Unlike powerbanks, the badges don’t have housings to protect them from mechanical damage. That’s what makes the badge a badge, of course, but the combination of unprotected cells, lack of a housing, and unfortunate PCB design oversights make a recipe for disaster.

Copper layer and solder mask

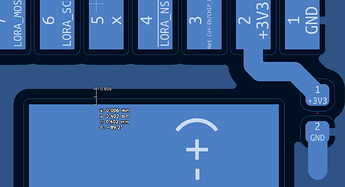

On the outer copper layer of the PCB, there are a GND plane and the “+” and “-” traces that are directly connected to the cells. The GND plane is connected, indirectly, to the “-” of the cell.

These copper areas are 0,4 mm apart.

Any inadvertent electrical connection between “+” and either GND or “-” constitutes a dangerous short circuit. This could by caused by something made from metal. The hazard is still present when the badge is switched off.

A component can eventually burn up and as such, open the circuit. In that sense, the problem may be self-limiting, but this may or may not happen fast enough to prevent reaching a temperature that is dangerously high. In a test setup with a WHY2025 badge and a 20 A external power supply (the cells can provide more than that!), it took too long, and the MOSFET became yellow glowing hot. That indicates a temperature of 2000 °C.

There is a protective circuit. There are polyfuses and there are the protections offered by the powerbank IC. Whether the chosen components are right for their purpose, was not assessed by us. Assuming these controls work as intended, everything behind them can be considered protected against short circuits.

The circuitry that connects the cells to the protections, on the other hand, can only be protected against short circuits mechanically, but there is no proper mechanical protection: the only mechanical protection present is the solder mask.

One cell’s unprotected “+” trace goes horizontally across the width of the board before it finally reaches its polyfuse. It is somewhat mechanically protected by the loudspeaker connector and (edit: the connector is not present in the final badges) the “compute module” (the M2 daughter board). The solder joints of the loudspeaker connector are, again, very close to both the GND plane and the cell “+” trace.

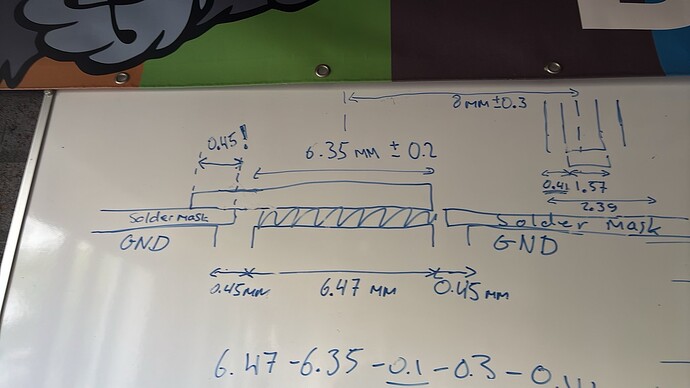

The solder mask is a very thin layer of resin (probably 10 to 30 µm (MICROmeter)) on top of the copper traces and planes. It is the outermost layer of the circuit board, and surrounds the components.

Solder mask is electrically insulating but easily damaged, and as such is insufficient as the only mechanical barrier if short circuits must be prevented.

The cell holder tabs

The cell holders have “tabs” that extend on both ends, that are soldered onto “pads” on the circuit board. These combined are part of the “footprint” of the part.

The footprint for the cell holders was designed for a different cell holder, but at some point another model was chosen. The footprint was kept as the new cell holder appeared to fit.

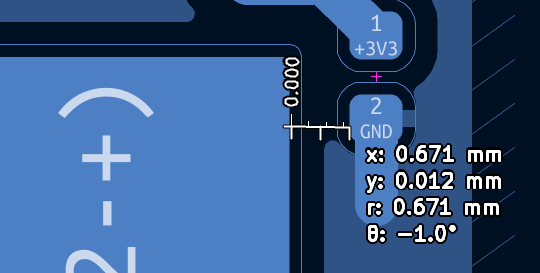

However, the pads for the cell holders are too small for the tabs. Due to tolerances in the manufacturing process, as specified in the manufacturer’s datasheet, there will be differences between individual badges. It is possible that in some badges, the tab will overlap with the GND plane or at least be very very close to it. The distance between the “+” pad and GND is designed at only 0,4 mm, and the sum of the tolerances is more than that. When the tab and the GND plane overlap, they are separated only by solder mask.

Exposed (uninsulated) solder joints (mitigated)

There is a GND solder joint very close (~ 0,6 mm) to the “+” pad of one of the cell holders. That was the first danger we saw. There are, however, also numerous other “+” and “GND” solder joints.

With these open solder joints, touching the badge to any shaped conductive material (e.g. jewelry or metal zippers) can cause a short circuit. If that short circuit occurs on the unsafe side of the protection circuitry, it can lead to a fire.

An attempt is going to be made to mitigate this specific risk by applying a layer of epoxy resin on top of the open solder joints. This should reduce the chance that something goes wrong, but since it does not address the other issues, we find it insufficient.

Exposed cell and cell holder contacts

Similar to the previous issue, even with the cells inserted into their holders, there remain parts of the “+” and “-” sides, that are uncovered.

Using the badge and having fun!

When powered from USB, the badge is probably safe to use (no guarantees though), at least within the realm of not catching fire. USB power sources should always provide short circuit protection for the cables and devices connected (but do buy only from trustworthy sellers).

Many short circuit protections in things like powerbanks and USB chargers are self-resetting, but some will sacrifice future functionality for the sake of immediate safety. At least it should be very unlikely to allow sufficient current to cause something to get glowing hot. (We did not test this.)

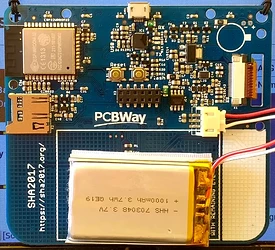

Comparison with earlier badges

The badges for MCH2022 and SHA2017 also did not have an adequate housing for the cells. They did, however, come with protected cells. The protection part of those cells had larger clearance distances, and two layers of yellow kapton tape (estimated at 120 µm thickness) for insulation, which is much more than the ~30 µm that you might get from a solder mask.

Danger is not boolean. The WHY2025 badge is more dangerous than the previous ones. Accepting the risk for previous badges should not imply accepting the risk for new ones, especially not a larger risk.

Image from Hackaday

Lessons for future badges

Some design patterns that would be merely sketchy or even completely fine in a properly enclosed product, can easily become dangerous when people wear and store a bare PCB. The bare PCB of a badge is more likely to get damaged than the PCB in a proper enclosure. Regular products typically come with a warning to stop using them if the case is showing signs of damage, but a badge typically doesn’t even come with a case. Solder mask can only be relied on to prevent short circuit protection against adjacent traces, if the solder mask itself is protected against mechanical damage.

There should be a proper review process and a high priority for keeping people safe.

(Co-)signatories

- Juerd

The following people have proof read the contents of this article and wanted to express that they agree:

- CH23

- f0x

- CensoredUsername

- Peetz0r

- illyau

- fk

- krekr

- pbx

- lmpsk

(Originally, I didn’t intend on having co-signatories, and in the interest of timely release, I didn’t ask all the experts, who advised on the matter, to sign.)

Personal note

I have nothing personal against the designers of the badge or the IFCAT board members. Communication and cooperation with IFCAT on the topic of disclosure has been friendly and professional. However, I still do think they’re making the wrong decision, to push forward with an unsafe badge and unprotected cells.

A public document like this may seem drastic. Going public was the last resort to reduce the risk of a fire breaking out. I’m concerned with fire in tents or luggage, and it keeps me up at night.

I’m also gut wrenched that this issue will now be a further burden to all parties involved, including the buildup crew and PL who are already very occupied with organizing the event itself. But I promised to do this and I think it’s really important.

Let’s have a great and fun camp, with fires only in the designated spots.

Timeline

Everything happened during the past few weeks, while I was also busy helping out with the heap of work for Team:Warehouse. Most of the time was spent trying to gather expert opinions and educating myself (I’m an utter newbie in electronics), and trying to convince the organization to change course (i.e. to not provide unprotected cells and to inform visitors that they shouldn’t use their own cells either). Everyone I asked agreed that there is a fire hazard, although not everyone ranks the individual risks the same. The back and forth between people takes a lot of time, and I just didn’t have the time to write an article earlier. Some have asked me to publish earlier, but I wanted to coordinate this with the foundation board first. By the time this document is published, they probably also have a statement ready.

- 2025-07-17 First problems identified in final prototype, destructive test conducted at hackerspace, IFCAT notified informally via Signal.

- 2025-07-17-20 More experts contacted for advice.

- 2025-07-20 Team:Badge had a meeting (contents unknown) and apparently decided to mitigate the solder joints, but not the rest.

- 2025-07-20 IFCAT notified formally by phone.

- 2025-07-25 Repeated plea (IRL) to IFCAT board member to not use the unprotected cells.

- 2025-07-28 Repeated plea (IRC) to different IFCAT board member to not use the unprotected cells.

- 2025-08-03 (during buildup) Public advisory written

- 2025-08-04 (during buildup) Meeting with IFCAT board members and someone from Team:Cohesion; final plea to change course; disclosure coordination

- 2025-08-05 (during buildup) Advisory published