Hi all, I just joined this forum specifically for this topic. I’m printing spacers and through those channels was made aware of these issues.

When I first saw the design, I was both in awe of its complexity and assuming the 18650 that were going to be distributed would come with protection circuitry. Safety obviously wasn’t neglected - there are several safeguards already built in.

Remember: Anything that can go wrong, will eventually go wrong. Especially during an event, with thousands of products distributed in harsh mechanical conditions. These cells, even with protection, are able to provide multiple Amperes of current, some even in the double digits.

I can already hear the sysadmin “ha ha people are stupid”-type banter if something happens. This is not acceptable. Attendees are people and people should be able to trust that anything they buy or are given doesn’t pose a hazard to them or their belongings. This is called compliance.

From a legal perspective: Even if the badge is given away and isn’t CE-marked, it is a product that is circulated (“in het economisch verkeer brengen” is the Dutch legalese) and therefore should follow best practices for product safety.

This means: always plan for first-order failures and mitigate risks. The main issues that stand out with this design:

Main issues (I think) not otherwise reported:

-

(Unprotected) Battery positive nets should have net class-defined minimum track widths with significant safety margin (200-300%). I’m looking at you, “Net-(BT1-+)” & “Net-(BT2-+)”"

-

Fuses should be as close to the parts they are protecting as possible, mostly because of the point outlined above

-

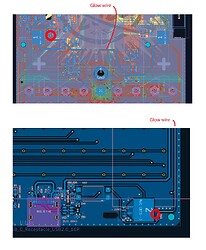

Even with these protections, a protected cell can still output a lot of current. I haven’t done any calculations, but the specified polyfuses have a trip current of 3.5A. If you’re using protected cells, they will have similar protection levels. Even if Net-(BT2-+) was behind that polyfuse (or builtin protection), the thin 0,2mm traces running al the way to the bottom of the board would still burn out if say R43/R48 was (will be!) short circuited to the negative terminal about a milimeter away, positioned on the edge of the board. It will become an ideal glow-wire ready to start a fire.

-

A similar issues is present at U3: its ground terminal is right next to an unprotected exposed battery contact (F2), creating a possible glow wire out of the (arguably thicker “Net-(BT2-+)”-trace running horizontally)

Other issues already reported

- Risk 1: Copper layer and solder mask:

- I fully concur, I have experienced this myself in a similar product with these holders.

- The cell holder tabs

- while somewhat receded, from my preliminary review these form the biggest issue since they can carry a lot of current and cannot be mitigated with some epoxy

- Exposed (uninsulated) solder joints (mitigated)

- The connections in the screenshots are from direct battery “+”-tabs to GND-planes, which is less dangerous than the issues I oulined above because there isn’t a long, thin trace involved.

- Even ‘potting’ these risks doesn’t provide a full mitigation. More so because this is not some ISO9001-operating manufacturing company, but a group of volunteers (doing their best!)

Mitigation

I’m proposing a minimally designed cover that covers the battery holders and adjacent electronics. I will work on this today and share the design. I know there already is a (beautifully designed) full enclosure by @dynom, but these take a lot more time to print.

This cover will function as an extra layer of protection on top of the epoxy.

Meta

For those wondering: I’m an industrial designer with 20yrs of experience. I have no formal training as an electrical engineer but have been working with electronics since I was about 6. I spearhead product compliance efforts at two medium sized companies. Some time ago I designed a device powered very much like the Konsool (it even had the same battery holders) that was first also supposed to use unprotected cells in parallel. During iterative prototyping and user testing, I quickly found out several of the same issues this badge has. Yes, some traces went up in flames and “someone” burnt their hand ![]()

Disclaimer

I’m not a lawyer and/or a trained electrical engineer. Also: This post is also not a ‘flame’ on the design or designers. I’m just trying to help. Thanks for making an awesome badge for this awesome event.